YiHai

-

Home

- About us

- Product

-

VF vacuum fryer for fruit and vegetable crisps

-

Low-temperature vacuum fryer

-

Vacuum freeze dryer

-

Quick-freezing machine

-

Pretreatment equipment

- Video

- Information

Pretreatment equipment

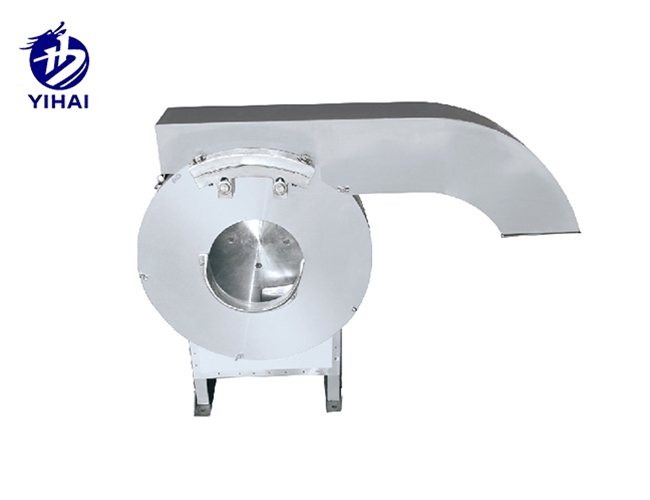

Name:Slicing and slicing machine

Name:Slicing and slicing machine

DetailsProduct Overview

The slicing and stripping machine is an automated food processing equipment specially designed for the food processing field. It is suitable for food processing plants, catering institutions, agricultural and sideline product cooperatives, supermarket fresh food areas, family workshops and other scenarios. It mainly solves the problems of low efficiency, inconsistent specifications, high labor costs and potential safety hazards in traditional manual food cutting. Through a precise transmission system and replaceable knife components, the equipment can quickly slice and strip root and tuber foods such as potatoes, sweet potatoes, carrots, onions, ginger, Chinese yams and lotus roots, as well as melon and fruit foods such as eggplants, cucumbers and green peppers. It can flexibly adjust the slicing thickness (0.5-10mm) and strip width (3-20mm). The cut foods have uniform specifications and smooth cut surfaces, which can meet different processing needs, greatly improve the efficiency of food preprocessing, and provide standardized foods for subsequent cooking, packaging, deep processing and other links.

Core Technologies

Precise Transmission and Positioning System : It is driven by a servo motor and equipped with a high-precision gear transmission structure. The transmission error is controlled within 0.1mm, ensuring that the food is stably pushed during the conveying process and avoiding the deviation of cutting specifications caused by food offset. At the same time, the equipment is equipped with an infrared positioning sensor, which can monitor the position of the food in real time and automatically adjust the running rhythm of the cutting knife, ensuring the consistency of the specifications of each slice and each strip of food, with a pass rate of more than 99%.

Replaceable Multi-functional Knife Components : The knives are made of food-grade stainless steel and undergo special quenching treatment. The hardness reaches HRC55 or above, with high sharpness, wear resistance and durability. The service life is 3-5 times that of ordinary knives. The equipment is equipped with various knife components such as slicing knives and stripping knives. The knife replacement is simple and convenient, no professional tools are needed, and the replacement can be completed in 1-2 minutes, meeting the slicing and stripping needs of different foods and realizing "one machine with multiple uses".

Intelligent Speed Control and Protection System : Equipped with an intelligent control system, the running speed of the equipment (0-60 times per minute) can be adjusted through the touch panel, which is flexibly adapted according to the hardness of the food and the cutting specifications. When processing hard root and tuber foods, the speed can be reduced to ensure smooth cutting; when processing soft melon and fruit foods, the speed can be increased to improve efficiency. In addition, the equipment is equipped with multiple safety protection devices, including an emergency stop button, a protective baffle and a two-hand start switch. When hands or foreign objects approach the cutting knife area, the equipment will stop immediately, effectively avoiding safety accidents.

Functional Features

Multi-functional Cutting : It supports two core functions of slicing and stripping. The slicing thickness and stripping width can be adjusted freely, which can meet the side dish needs of the catering industry (such as shredded potatoes, carrot slices), the standardized production needs of food processing plants (such as slicing potato chip raw materials, stripping French fries raw materials) and the food processing needs of daily family cooking. It is applicable to a wide range of foods, and there is no need to purchase multiple additional devices.

Efficient and Stable : It can process 200-1000 kg of food per hour (depending on the equipment model and food type), which is 8-15 times the efficiency of manual cutting, greatly shortening the food processing time, especially suitable for batch processing scenarios. The equipment has small vibration and low noise (noise ≤ 65 decibels) during operation, making the working environment more comfortable. The core components have undergone strict aging tests, and there is no fault in continuous operation for 8 hours, with strong stability.

Easy to Clean and Maintain : The equipment body is made of food-grade 304 stainless steel, and the surface is treated with wire drawing, which is smooth and free of dead corners, and not easy to be contaminated with food residues and oil stains. It can be cleaned by simply rinsing with clean water, saving time and effort. The internal structure of the equipment is designed simply, and the key components are detachable. Daily maintenance only needs to regularly check the wear of the knife and lubricate the transmission components. The maintenance cost is low, and basic maintenance can be completed without professional maintenance personnel.

Humanized Design : The feed port adopts an inclined and widened design, with a feed diameter of up to 150mm, which is convenient for putting in large pieces of food without pre-cutting the food in advance. The discharge port is equipped with a height-adjustable receiving rack, which can be adapted to receiving containers of different heights to avoid food falling and causing waste. The control panel adopts a high-definition LCD screen, the operation buttons are clear and easy to understand, and it has Chinese and English bilingual operation interfaces, so novices can quickly get started without training.

Application Fields

Food Processing Industry : It is used in potato chip factories, French fries factories, canned food factories, frozen food factories, etc., to perform standardized slicing and stripping of raw materials. For example, potatoes are sliced for making potato chips, and sweet potatoes are stripped for making frozen sweet potato strips, ensuring uniform product specifications and meeting the needs of large-scale production.

Catering and Group Meal Industry : It is suitable for large restaurants, central kitchens of chain catering, school canteens, enterprise canteens, etc., to quickly process side dish ingredients needed daily, such as cutting shredded potatoes, carrot slices, onion rings, etc., reducing the labor input in the kitchen, improving the meal preparation efficiency, and ensuring the speed of food serving and the consistency of quality.

Agricultural and Sideline Product Processing Industry : In agricultural and sideline product cooperatives and agricultural product processing plants, it is used for the initial processing of freshly picked root and tuber, melon and fruit agricultural products. After being cut into standardized slices and strips, they are vacuum-packed or dried, which improves the added value of agricultural products, extends the shelf life, and expands the sales channels.

Supermarket and Family Scenarios : Supermarket fresh food areas can be equipped with small slicing and stripping machines to provide on-site food cutting services for consumers, meeting the diverse needs of consumers and improving the service quality of supermarkets; family workshops or individual families use small desktop models, which can easily process the food needed for daily cooking, save cooking time, and avoid the safety hazards of manual cutting.

After-sales Service

We always adhere to the concept of "taking users as the center and providing high-quality services" and provide users with comprehensive after-sales service support to ensure that users have no worries about use:

Personalized Selection Guidance : According to the user's use scenario, the type of processed food, the expected processing volume and other needs, provide professional equipment selection suggestions, recommend the most suitable model and configuration, ensure that the equipment can fully meet the user's actual use needs, and avoid resource waste.

Free Installation, Commissioning and Training : For industrial-grade and medium-sized equipment, free on-site installation and commissioning services are provided to ensure the normal operation of the equipment; at the same time, on-site technical training is provided for operators, including equipment operation, knife replacement, daily maintenance, fault diagnosis, etc., to ensure that operators can proficiently master the equipment use skills.

Quality Assurance and Maintenance Services : The equipment has a 1-year overall quality assurance, and the core components (servo motor, knife, transmission gear) have a 2-year quality assurance. During the warranty period, if the equipment has quality problems, we will provide free maintenance services and replacement of damaged parts. The maintenance personnel will respond within 24 hours after receiving the repair information and arrive at the site within 48 hours (except for remote areas).

Lifelong Maintenance and Accessory Supply : After the equipment exceeds the warranty period, we still provide

Hot Products

We can process and customize the products

Contact us immediatelyShandong Yihai Industrial Equipment mainly deals in food frying equipment such as VF vacuum low-temperature dehydration (fryer) machines and FD vacuum freeze dryers

Yihai Industrial

Contact us

Contact person: Lawrence.Hu

Phone:+86 195 7774 4855

WeChat: +86 195 7774 4855

Email:yihaigongye@gmail.com

Website:www.sdyhgyzb.com

Address:Pule Industrial Park, Mizhou Sub-district, Zhucheng City, Shandong Province

NewsInformation

more+- What fields can vacuum fryer be applied to 2025-09-22

- The process flow of vacuum fryer cleaning 2025-08-13

- Characteristics of Continuous Vacuum Frying Machine 2025-08-13

Copyright © 2025 Shandong Yihai Industrial Equipment Co., LTD All Rights Reserved.Privacy Policy - About us