YiHai

-

Home

- About us

- Product

-

VF vacuum fryer for fruit and vegetable crisps

-

Low-temperature vacuum fryer

-

Vacuum freeze dryer

-

Quick-freezing machine

-

Pretreatment equipment

- video

- Information

Pretreatment equipment

Classify

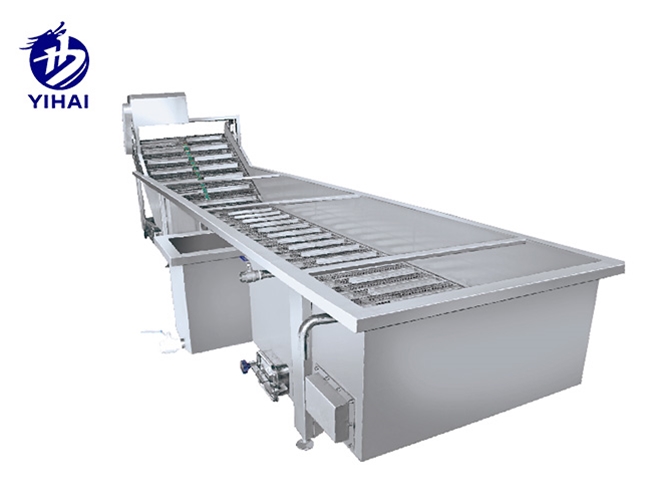

Cooling assembly line

Product Overview

The cooling assembly line is a key supporting equipment after food processing, suitable for fruit and vegetable processing plants, meat processing plants, frozen food factories, bakeries and other scenarios. It solves the problems of low efficiency, easy contamination and quality degradation of natural cooling after food processing. Through cold air, cold water or ice water bath, the equipment quickly cools down high-temperature food materials that have just undergone blanching, cooking and baking, reducing the temperature of food materials to a range suitable for subsequent processing or storage in a short time. This prevents bacteria from breeding in food materials due to long-term high temperature, while retaining the taste, nutrition and color of food materials.

Core Technologies

Multi-mode Temperature Control System:Supports three cooling modes: cold air cooling, cold water spray cooling and ice water bath cooling. The temperature control range is 0-25℃, with a temperature control error of ±1℃. The suitable cooling method can be selected according to the characteristics of food materials (such as heat sensitivity, shape).

Precise Conveying Speed Regulation Structure:Adopts food-grade PVC conveyor belt or stainless steel mesh belt, with adjustable conveying speed of 0.3-5m/min. Combined with the segmented cooling area design, it ensures that food materials can fully contact the cooling medium in different cooling stages, achieving uniform temperature reduction.

Energy-saving Circulation System:The cold air mode is equipped with a return air filter device to recover part of the cold energy and reduce energy consumption; the cold water/ice water bath mode adopts a water circulation filter system, and the cooling water can be recycled, with a water saving rate of over 40%, reducing operating costs.

Core Advantages and Functions

Fast and Efficient Cooling:It can reduce the temperature of food materials from 80-120℃ to 5-20℃ within 5-30 minutes (the specific time depends on the characteristics of food materials). The cooling efficiency is 6-10 times that of natural cooling, which greatly shortens the processing cycle and improves the overall production efficiency.

Adaptable to Multiple Food Materials:It can process various forms of food materials such as leafy vegetables, roots, meat, baked food and frozen semi-finished products. Whether it is bulk, bagged or block food materials, stable cooling can be achieved without frequent replacement of equipment accessories.

Safety and Sanitation Guarantee:The machine body and parts in contact with food materials are made of 304 stainless steel or food-grade PVC, which meets food hygiene standards; the equipment is equipped with an automatic cleaning function, and regular cleaning can prevent bacteria from breeding in residual food materials, ensuring food safety.

Strong Cost Controllability:The energy-saving circulation system reduces water and electricity consumption, and automatic operation reduces manual on-duty costs; the equipment has a low failure rate and simple maintenance, which can reduce comprehensive operating costs in long-term use.

Convenient and Flexible Operation:Adopts a touch screen control system, which can preset cooling parameters (temperature, speed, time) for different food materials and start with one key; supports linkage with front and rear processing equipment to achieve seamless connection of automated production lines.

Application Fields

Fruit and Vegetable Processing:Quickly cool blanched vegetables such as spinach, broccoli and carrots, preparing for subsequent dicing, packaging or freezing processes, and preventing vegetables from softening and deteriorating.

Meat Processing:Cool just-cooked braised meat, sauced meat or fresh meat after slaughtering, quickly reducing the temperature to a level suitable for cutting and packaging, inhibiting bacterial reproduction and extending the shelf life.

Baking and Pastry Processing:Cool freshly baked baked foods such as bread, cakes and biscuits, avoiding moisture regain and deformation caused by packaging at high temperature, and maintaining the crispy taste of food.

Frozen Food Processing:Cool pre-processed frozen semi-finished products such as dumplings, meatballs and chicken nuggets, reducing their temperature to near freezing point, laying a foundation for subsequent quick freezing processes and ensuring product quality.

After-sales Service

Customized Solutions:Provide customized cooling assembly line design solutions according to the user's food material type, output, cooling demand and workshop site, ensuring that the equipment adapts to the production process.

Installation and Commissioning:A professional team provides on-site free installation and commissioning of the equipment, and simultaneously trains operators to ensure that the equipment is quickly put into normal operation.

Quality Assurance and Maintenance:1-year warranty for the whole machine, 2-year warranty for core components (refrigeration unit, conveyor motor, temperature control system); respond within 24 hours after equipment failure, and provide on-site maintenance within 48 hours (except for remote areas).

Lifelong Maintenance and Accessory Supply:Provide lifelong maintenance services, and only charge reasonable cost fees beyond the warranty period; supply vulnerable parts such as refrigeration accessories, conveyor belts and filters for a long time to ensure the continuous and stable operation of the equipment.

Previous:Blanching and finishing line

We can process and customize the products

Contact us immediatelyShandong Yihai Industrial Equipment mainly deals in food frying equipment such as VF vacuum low-temperature dehydration (fryer) machines and FD vacuum freeze dryers

Yihai Industrial

Contact us

Contact person: Lawrence.Hu

Phone:+86 195 7774 4855

WeChat: +86 195 7774 4855

Email:yihaigongye@gmail.com

Website:www.sdyhgyzb.com

Address:Pule Industrial Park, Mizhou Sub-district, Zhucheng City, Shandong Province

News - About us